How Velfab Ensures Precision in Marine-Grade Machined Components

In the demanding world of marine engineering, components must not only fit and perform effectively but also withstand the test of time. Saltwater corrosion, constant vibration, high pressure, and heavy loads make the marine environment one of the toughest on earth.

At Velfab, precision isn’t just a process; it’s a promise. With advanced CNC machining and engineering expertise, we deliver marine-grade components that meet the highest standards of accuracy, reliability, and endurance.

Based in Australia, Velfab supports leading marine, offshore, and defence operations with components engineered to survive the harshest ocean conditions and meet international performance standards. Here’s how we maintain precision from start to finish and why it matters for your operations.

Understanding the Demands of Marine Engineering

The marine environment is relentless. Components are exposed to saltwater corrosion, temperature fluctuations, and continuous vibration. These conditions push materials and tolerances to their limits. Unlike many industries where a part can be easily replaced, marine components often operate in conditions where downtime leads to costly disruptions and safety risks.

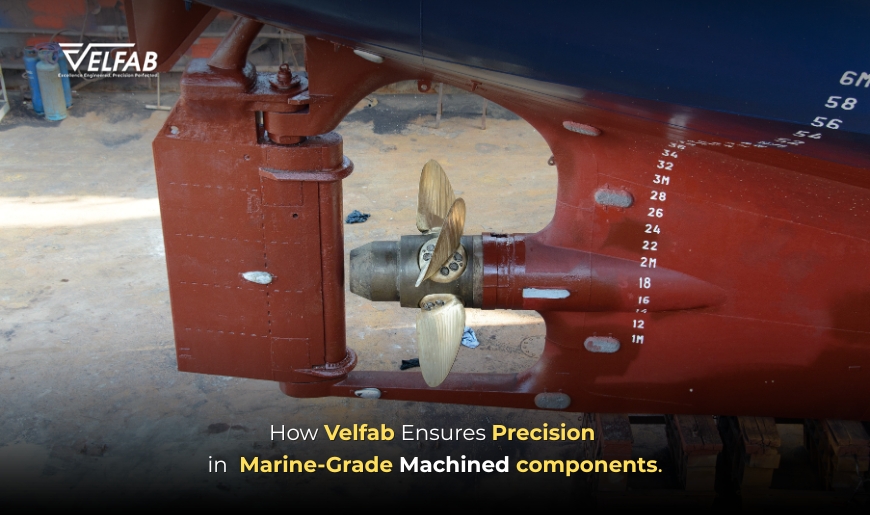

That’s why precision machining plays a critical role. It ensures every component, from propeller hubs to valve bodies, is engineered to exact specifications, maintaining performance even in the most extreme environments.

How Velfab Executes Precision Machining for Marine Applications

1. Marine-grade material selection

Durability begins with the right material. Velfab utilizes duplex stainless steel, aluminum bronze, and titanium alloy metals renowned for their exceptional corrosion resistance and mechanical strength. These materials withstand saltwater, pressure, and mechanical stress while maintaining the precision required for performance-critical parts.

2. Advanced machining processes

Utilizing advanced CNC and multi-axis machining, Velfab achieves tight tolerances and superior finishes for complex geometries such as propeller hubs, manifolds, and thruster components. Consistency across every detail ensures a perfect fit and long-term reliability.

3. Engineering and design collaboration

Precision begins at the design stage. Our engineers collaborate closely with clients to refine designs for manufacturability, durability, and cost efficiency. This partnership approach ensures every part is optimized for both performance and serviceability.

4. Rigorous inspection and quality assurance

Every component undergoes strict dimensional, surface, and tolerance checks. With full process traceability and inspection protocols, Velfab guarantees consistency, compliance, and precision in every part we produce.

5. Lifecycle focus and reliability

Downtime in marine operations can be costly. Velfab’s precision machining approach focuses on minimising maintenance and maximising uptime, ensuring each component delivers dependable performance and extended service life.

Marine Components Engineered with Precision

Velfab specialises in precision machining for marine components, including:

- Propellers, shafts, and thruster parts

- Hydraulic and pump housings

- Valve bodies and structural brackets

- Custom machined fittings, casings, and stabiliser systems

Each part is crafted from corrosion-resistant alloys to endure high loads, resist seawater degradation, and maintain dimensional stability. This ensures smooth performance and minimal downtime for operators in the most demanding marine conditions.

Final Thoughts

The sea is an uncompromising environment, but with the right engineering, precision becomes protection. At Velfab, we combine technology, experience, and craftsmanship to deliver marine-grade machined components built for endurance, safety, and reliability.

From propeller systems to hydraulic housings, every component reflects our commitment to marine-grade precision machining in Australia. Because true precision isn’t just measured in microns, it’s measured in trust.