Guide to CNC Precision Machining Tools and Processes

When was the last time you looked at a product and thought, “How do they even make something this accurate?” Whether it’s the engine inside your car, a complex aerospace component, or even the surgical tools used in hospitals, there’s a high chance precision machining played a crucial role in bringing that product to life.

At Velfab, we know that behind every perfect cut, every micrometer-level detail, and every flawless finish lies a world of cutting-edge CNC tools and processes. In this blog, we’re diving deep into the tools and techniques that power CNC precision machining and why it’s the backbone of modern manufacturing

So, What Exactly Is Precision Machining?

Let’s keep it simple. Precision machining is the process of cutting, shaping, or removing material from a workpiece—typically metal or plastic—to create parts with tight tolerances (often within ±0.005mm). It’s not just about making things small; it’s about making them perfect.

In industries where there’s zero room for error—think aerospace, defense, automotive, medical—precision machining ensures reliability, consistency, and quality.

The Heartbeat of Precision: CNC Machining

CNC stands for Computer Numerical Control—a fancy way of saying machines are programmed to follow exact instructions, down to the tiniest detail. No guesswork. No manual tweaking.

Using CAD/CAM software, engineers feed digital designs directly into CNC machines. The result? Unmatched accuracy, efficiency, and repeatability.

The Key Tools Behind CNC Precision Machining

CNC Milling Machines

Think of these as the sculptors of the manufacturing world. Milling tools rotate at high speeds, carving material away in multiple directions. Perfect for complex surfaces and geometries.

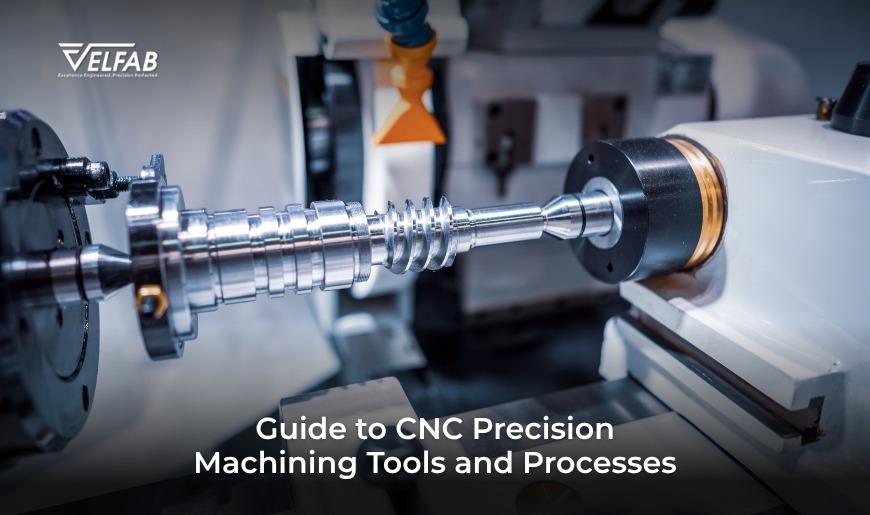

CNC Turning Machines (Lathes)

These spin the material while a tool moves along it—ideal for symmetrical objects like shafts and rods. High precision? Absolutely.

CNC Grinding Machines

These are all about finishing. When you need a smooth, shiny, dimensionally accurate surface, CNC grinders do the magic.

CNC EDM (Electrical Discharge Machines)

For materials that are too tough to cut with traditional tools, EDM uses sparks to shape parts without direct contact. It’s often used in mold-making or intricate dies.

Why Does Precision Matter?

Precision isn’t just a buzzword it’s a standard. A small flaw in a machined part can lead to major product failures. A 0.01mm misalignment in an aircraft component? That’s a risk no one wants to take.

That’s why manufacturers worldwide trust experts like Velfab, where every step of the machining process is handled with care, technology, and a deep understanding of tolerances and materials.

Challenges in Precision Machining (And How We Solve Them)

Tool Wear and Tear

Even the toughest tools degrade over time. At Velfab, we monitor tool wear in real-time and replace tools proactively to avoid any dip in quality.

Material Behavior

Different materials respond differently to heat, pressure, and cutting. We use simulation software to predict this behavior before making the first cut.

Thermal Expansion

Machines and materials expand under heat. We combat this with climate-controlled environments and real-time sensors to maintain tolerances.

The Future of CNC Precision Machining

With AI and automation stepping in, precision machining is evolving faster than ever. Smart CNC machines now learn from every job, adjusting speeds, tool paths, and pressure on the fly to enhance both speed and precision.

At Velfab, we’re not just keeping up—we’re pushing boundaries. Our investment in advanced CNC systems, skilled operators, and real-time quality checks ensures that every component we produce meets the highest standards every time.

Final Thoughts

Precision isn’t a luxury; it’s a necessity. Whether it’s for life-saving medical tools or the sleek interiors of luxury vehicles, precision machining lies at the heart of innovation.

If you’re looking for reliable, future-ready CNC machining solutions, Velfab is your trusted partner. Get in touch today, and let’s build perfection micron by micron.