What to Look for in a Precision Machining Partner: A Checklist for OEMs

Finding the right precision machining partner is a big deal for any Original Equipment Manufacturer (OEM). After all, the quality of your parts directly impacts the performance of your products. Whether you’re working on a large-scale project or a small batch of custom parts, having the right team behind you can make all the difference. But with so many options out there, it’s easy to feel overwhelmed.

So, what should you be looking for when choosing a precision machining partner? In this post, we’ll break it down with a straightforward checklist to guide you through the process. Let’s dive in!

1. Expertise in Precision Machining

First and foremost, your machining partner needs to know their stuff. Precision machining is all about producing parts with incredibly tight tolerances—there’s no room for error. If your partner doesn’t have the technical know-how or experience to handle such precision, it’s going to show in the final product.

Look for a partner with a proven track record. Ask about their experience with similar projects, industries, and materials. Don’t be shy about asking for references or examples of their previous work. You want to make sure they’ve got the chops to deliver the kind of quality you’re expecting.

Key Questions to Ask:

- How much experience do they have in your specific industry or with your type of project?

- Do they specialize in any particular types of precision machining?

- Can they meet your specific design and material requirements?

2. Advanced CNC Machining Solutions

CNC (Computer Numerical Control) machining has become the gold standard for precision manufacturing. The ability to create highly accurate, repeatable parts with minimal human error is essential for today’s fast-paced industries.

Your partner should be up-to-date with the latest CNC Machining technology. This not only helps speed up production but also improves accuracy and reduces waste. If a partner is still using outdated machines, it could slow down your project and increase the likelihood of mistakes.

Why It’s Important:

- Modern CNC machines offer high precision, ensuring your parts are exactly as you need them.

- They make it easier to scale production without sacrificing quality.

- A partner with top-of-the-line CNC equipment can adapt to your needs, whether you’re producing small batches or high-volume runs.

3. Custom Machining Services for Your Unique Needs

OEMs often need more than just standard machining solutions. You might require custom parts, special modifications, or even prototypes. That’s where custom machining services come in.

A good machining partner should be flexible enough to adapt to your unique requirements. Whether you’re working with a one-off prototype or a low-volume production run, they should be able to offer tailored services to meet your specific needs.

Why Custom Machining is a Game-Changer:

- You can get exactly the parts you need without compromising on design.

- Custom services offer greater flexibility, whether you’re creating a unique prototype or tweaking a product for a new market.

- Your partner can help solve tricky design challenges that might not be possible with off-the-shelf solutions.

4. A Commitment to Manufacturing Quality Assurance

Nothing is more frustrating than receiving parts that don’t meet your expectations or have hidden defects. A solid quality assurance (QA) process is vital to prevent this from happening. Your machining partner should have strict QA procedures in place to ensure that every part meets your exact specifications.

A well-established QA system means that from the moment your materials enter the workshop, every step of the process is carefully monitored. Whether it’s using precision measurements or running non-destructive tests, your partner should leave no stone unturned when it comes to ensuring quality.

Key Things to Look For:

- Do they have certifications like ISO 9001 or other industry-standard quality assurance systems?

- How do they monitor and control the quality of the parts they produce?

- Are they transparent about their testing and inspection processes?

5. Communication and Customer Service

In the world of precision machining, good communication is just as important as technical skill. You need a partner who listens to your needs, keeps you updated on the status of your project, and is responsive when you have questions or concerns.

A good machining partner will make sure that you’re always in the loop. They should be able to clearly explain any technical details and address any issues that come up during production. Communication can prevent small problems from becoming big ones, so it’s essential that your partner is both approachable and proactive.

Why It Matters:

- Clear communication helps prevent misunderstandings and delays.

- Being kept informed throughout the process means you can make decisions quickly.

- A good working relationship makes collaboration smoother and more productive.

6. Cost-Effectiveness and Value

While quality should always come first, we can’t ignore the price. Choosing a machining partner with fair pricing while maintaining high quality is essential. That said, don’t just go with the cheapest option—you want to ensure you’re getting good value for your investment.

Sometimes, opting for a lower-priced service can end up costing more in the long run if the parts don’t meet quality standards or if the project takes longer than expected. Make sure you understand what’s included in the price, and look for a partner who offers transparency and value-added services, like design support or on-time delivery.

Key Questions to Ask:

- Is the pricing model transparent, without any concealed charges?

- Is the quality proportional to the investment you are making?

- Does the partner offer any extra services that could save you time or money?

Conclusion

Selecting the ideal precision machining partner is a crucial choice that can greatly influence your business’s success. By prioritizing expertise, advanced CNC machining, custom solutions, quality assurance, clear communication, and cost-effectiveness, you’ll be well-positioned to secure a partner that aligns with your objectives.

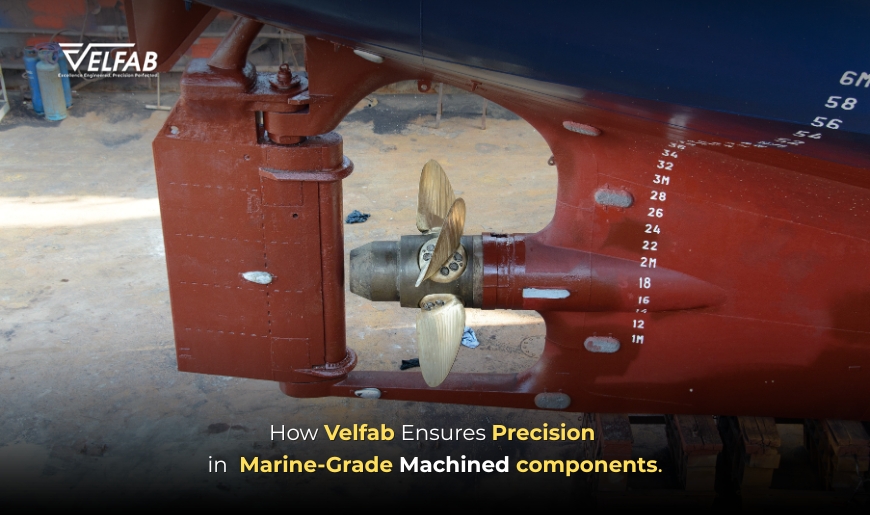

Remember, your machining partner isn’t just a supplier—they’re an extension of your team. Take the time to find one that aligns with your values, understands your needs, and is invested in helping you succeed. The right partnership will not only ensure you get the best parts, but also set you up for long-term success. Looking for unmatched precision machining? Velfab Engineers ensures superior quality and innovation. Let’s collaborate for excellence!