Top 10 CNC Machined Components Used in Marine Application

When it comes to marine engineering, precision is everything. CNC machining offers the repeatability and tight tolerances required for marine-grade components to withstand harsh environments and brutal sea conditions. Let’s explore the top 10 CNC-machined components essential in marine applications components that power, steer, secure, and sustain vessels of all types.

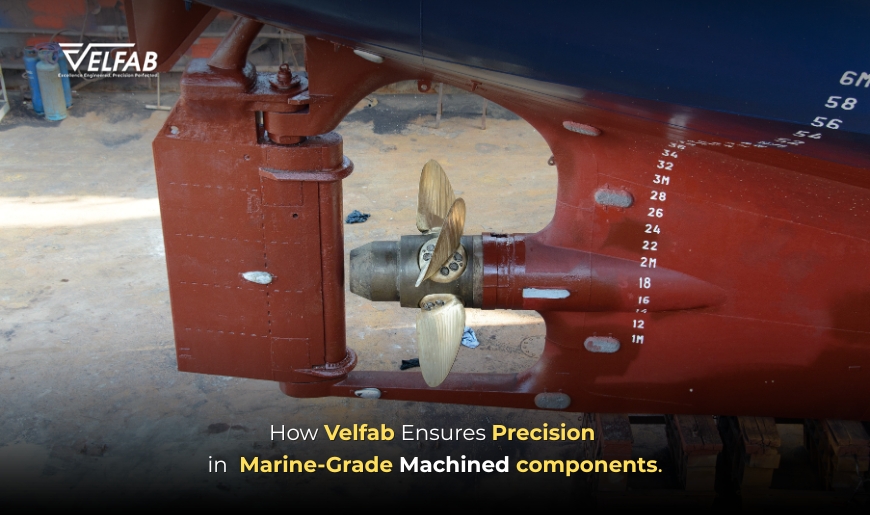

1. Propellers

The propeller is arguably the most vital component in a boat’s propulsion system. CNC machining ensures exceptional precision in blade pitch, shape, and balance. This translates into optimal hydrodynamic performance, whether you’re aiming for top speed or fuel efficiency. CNC expertise eliminates inconsistencies, enabling innovations in design that enhance speed, thrust, and control.

2. Engine Components

From pistons and cylinder heads to crankshafts and camshafts, engine parts must endure intense heat and pressure. CNC-machined components offer the tight tolerances and superior surface finishes required for efficient combustion, greater reliability, and longer engine life. Plus, custom CNC machining allows bespoke modifications—like optimized ports—for tailored performance.

3. Rudders

Critical for steering and maneuverability, CNC-machined rudders feature precise hydrodynamic profiles that reduce drag while enhancing control. Crafted from corrosion-resistant materials such as stainless steel, they allow vessels—especially racing or high-performance boats—to respond quickly and accurately.

4. Drive Shafts

These parts transmit power from the engine to the propeller and must handle torque without wobble. CNC machining delivers precisely round and perfectly balanced shafts made from lightweight yet robust materials like stainless steel or titanium—reducing vibration and improving propulsion system reliability.

5. Gearboxes

Gearboxes demand intricate accuracy. CNC machining ensures that gears and housing components mesh perfectly and align precisely—enabling efficient power transfer, improved acceleration, and higher top speeds for performance-driven vessels.

6. Control System Components

Whether it’s throttle assemblies, steering linkages, or electronic housing, control system parts must function flawlessly. CNC machining delivers precise fits and consistent performance, ensuring smooth responses and greater safety—especially in high-speed or competitive marine environments.

7. Hull Fittings

Thru-hulls, valves, and strainers form the physical connection between the boat and the sea. These components must maintain watertight integrity under constant duress. CNC machining ensures exact tolerances and corrosion resistance, offering reliable long-term performance in saltwater environments.

8. Fuel System Components

Fuel delivery systems including injectors, pumps, and filters must be precise and durable. CNC-machined components guarantee leak-free operation and consistent fuel flow, enhancing performance and efficiency while minimizing failure risks.

9. Steering System Parts

Precision-machined hydraulic cylinders, linkages, and helm units are essential for accurate steering. CNC ensures tight clearances and smooth operation, providing precise handling and quick response—especially vital in racing or high-speed cruising scenarios.

10. Exhaust Systems

To maximize engine output, exhaust components like manifolds, risers, and mufflers must optimize flow while resisting corrosion. CNC machining delivers crafted shapes in stainless steel or aluminum that minimize backpressure and enhance performance and efficiency.

Why CNC Machining Matters in Marine Applications

Exacting Precision & Consistency: From propellers to fuel filters, marine components must meet tight tolerances. CNC provides repeatable accuracy across production runs.

Material Versatility & Durability: Corrosion-resistant metals like stainless steel, titanium, and specialty alloys can be machined reliably, ensuring components withstand saltwater and wear.

Customization & Speed: Whether it’s optimizing engine ports or tailoring hull fittings, CNC allows rapid prototyping and bespoke manufacturing—critical for custom marine applications.

Enhanced Performance & Reliability: Precision parts reduce vibration, improve alignment, deliver power efficiently, and contribute to smoother steering and safer operation.

Final Thoughts

For Velfab, understanding the significance of CNC-machined components in marine design isn’t just about technology—it’s about elevating vessel performance, longevity, and safety. Each of these top 10 components plays a pivotal role, and CNC technology ensures they excel, whether powering a yacht, steering a speedboat, or outfitting a deep-sea rig.