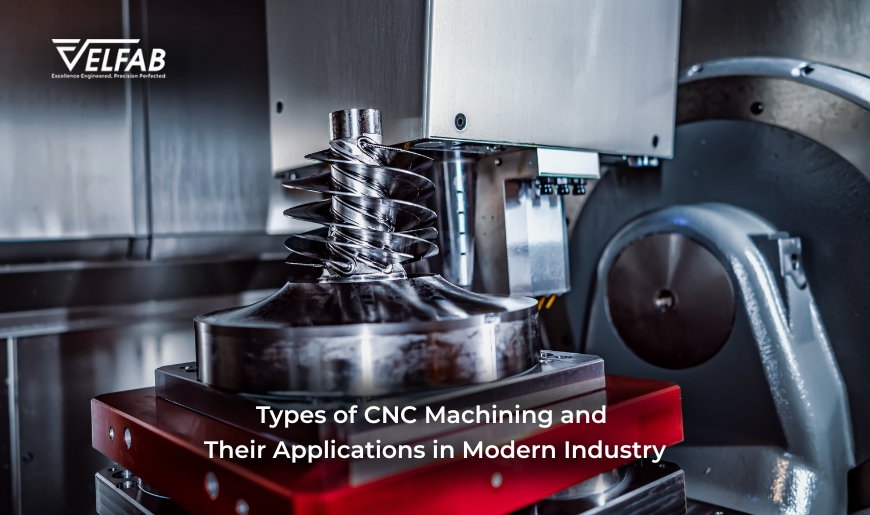

Walk into any modern manufacturing unit today, and you’ll most likely find CNC machines quietly shaping the future—quite literally. From automotive components to delicate medical implants, CNC machining is at the heart of how industries bring precision, speed, and consistency to production. But what exactly are the different types of CNC machines? And how do […]

Finding the right precision machining partner is a big deal for any Original Equipment Manufacturer (OEM). After all, the quality of your parts directly impacts the performance of your products. Whether you’re working on a large-scale project or a small batch of custom parts, having the right team behind you can make all the difference. […]

When you think about Australia’s marine and mining industries, it’s easy to imagine vast operations with heavy machinery dealing with extreme conditions. But behind the scenes, there’s something even more important: precision engineering. For these sectors to thrive, equipment needs to perform flawlessly under pressure, and that’s where Velfab Precision Engineering makes all the difference. […]

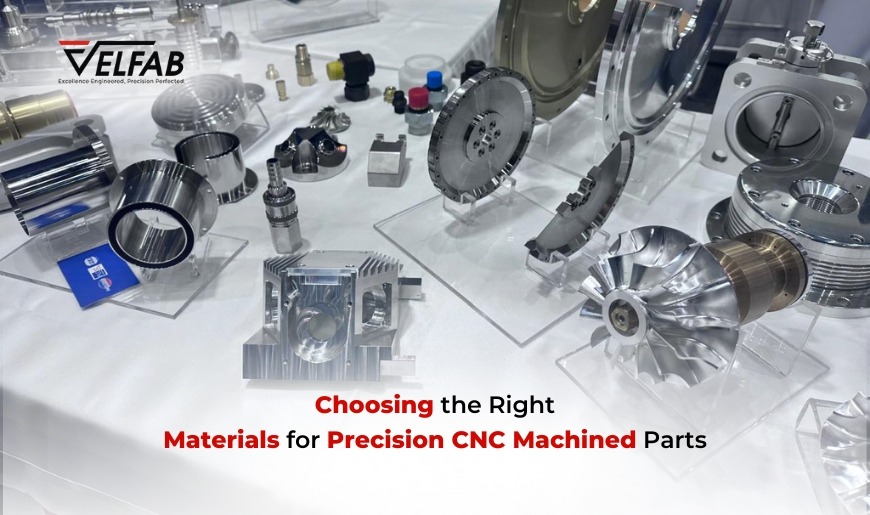

Choosing the appropriate materials for precision CNC machined parts is crucial to ensure optimal performance, durability, and cost-effectiveness. The material selection impacts not only the functionality of the component but also the efficiency of the machining process itself. In this guide, we will explore key considerations to help you make informed decisions when selecting materials […]

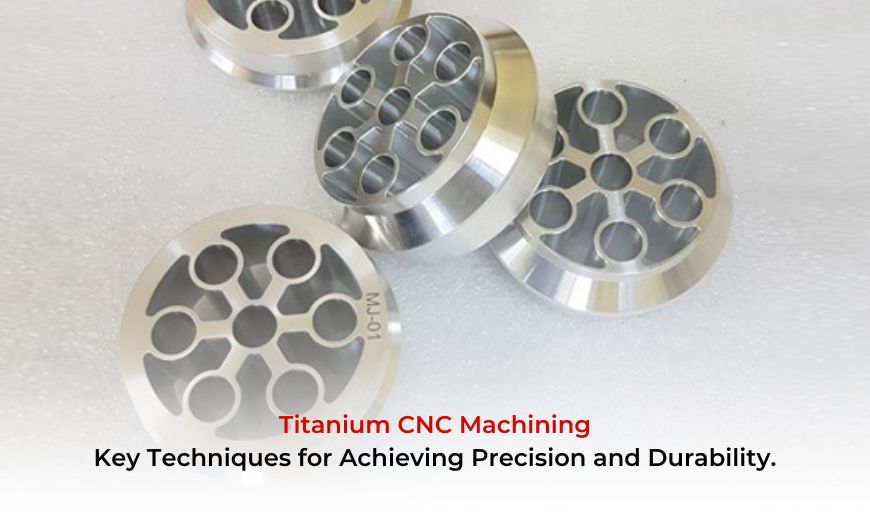

When it comes to tough, lightweight, and high-performance materials, titanium is a top contender in many industries. But machining titanium isn’t as simple as cutting through softer metals. This material poses unique challenges, from its strength and toughness to its tendency to heat up quickly during the machining process. Yet, the demand for titanium in […]

- 1

- 2