Designing machined components is a balancing act between functionality, cost, and manufacturability. Even small design oversights can lead to higher production costs, extended lead times, or even manufacturing failures. At Velfab, we emphasize the importance of DFM (Design for Manufacturability) in machining to help our clients create parts that are efficient, cost-effective, and easy to […]

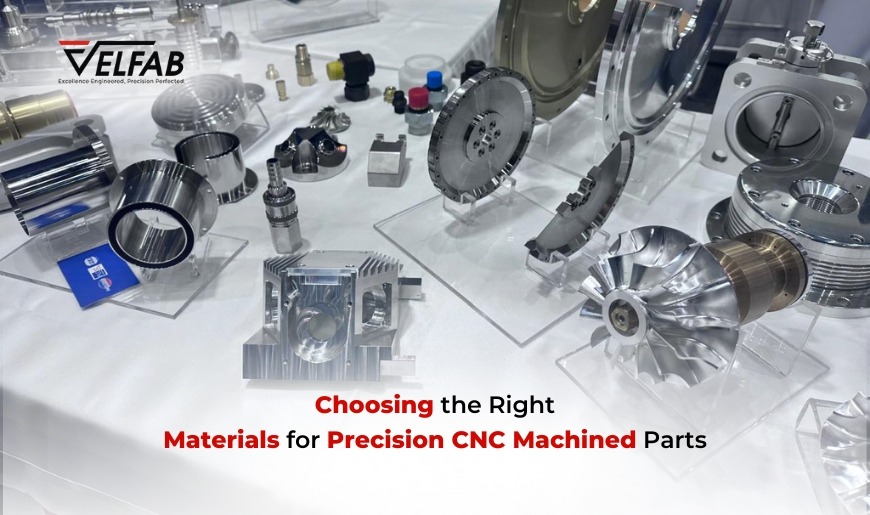

Choosing the appropriate materials for precision CNC machined parts is crucial to ensure optimal performance, durability, and cost-effectiveness. The material selection impacts not only the functionality of the component but also the efficiency of the machining process itself. In this guide, we will explore key considerations to help you make informed decisions when selecting materials […]

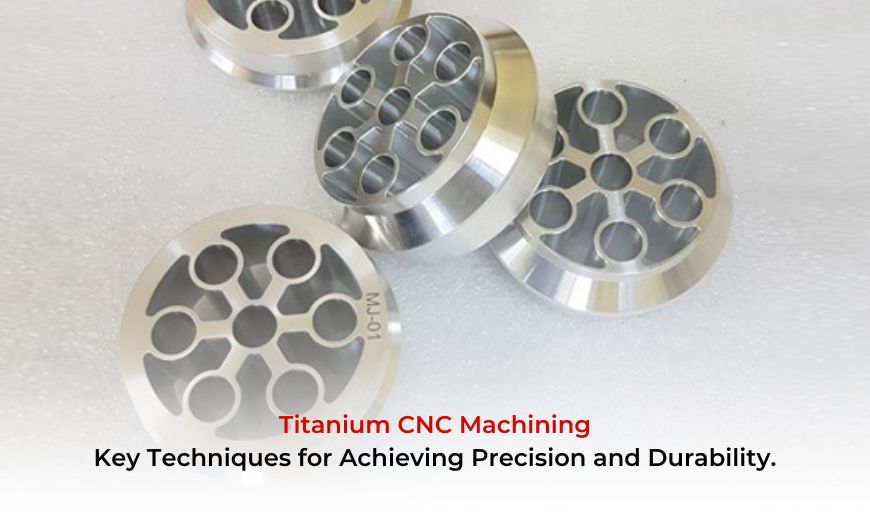

When it comes to tough, lightweight, and high-performance materials, titanium is a top contender in many industries. But machining titanium isn’t as simple as cutting through softer metals. This material poses unique challenges, from its strength and toughness to its tendency to heat up quickly during the machining process. Yet, the demand for titanium in […]

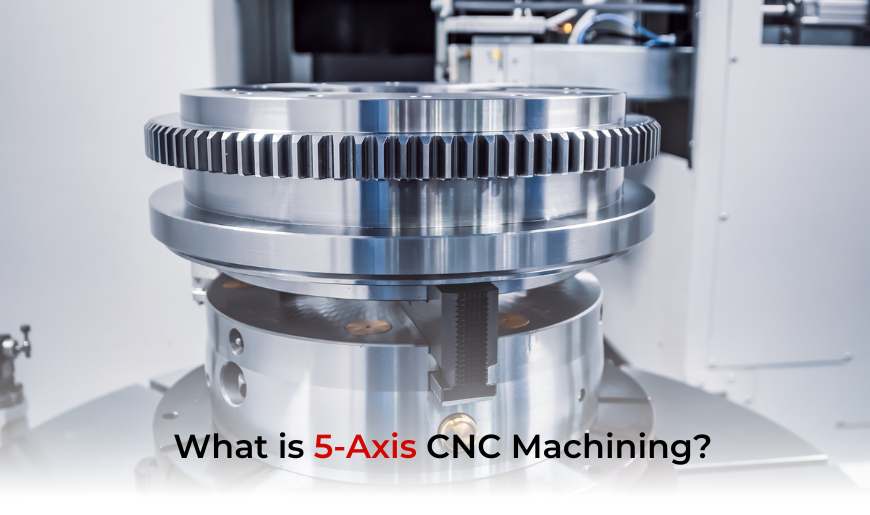

In manufacturing, where every fraction of a millimeter counts, the ability to craft complex, precise parts is what sets leading companies apart from the rest. Imagine creating a part that requires machining from multiple angles, without needing to reposition it over and over. This is where 5-axis CNC machining takes center stage a breakthrough technology […]