How Precision Machining Reduces Downtime in Oil & Gas Operations

In the oil and gas sector, time is money—literally. Every minute of downtime in a drilling rig, pipeline, or refinery operation translates into lost production, missed targets, and mounting costs. Studies estimate that unplanned downtime can cost oil and gas companies millions of dollars each year, especially when offshore rigs or critical processing plants are involved.

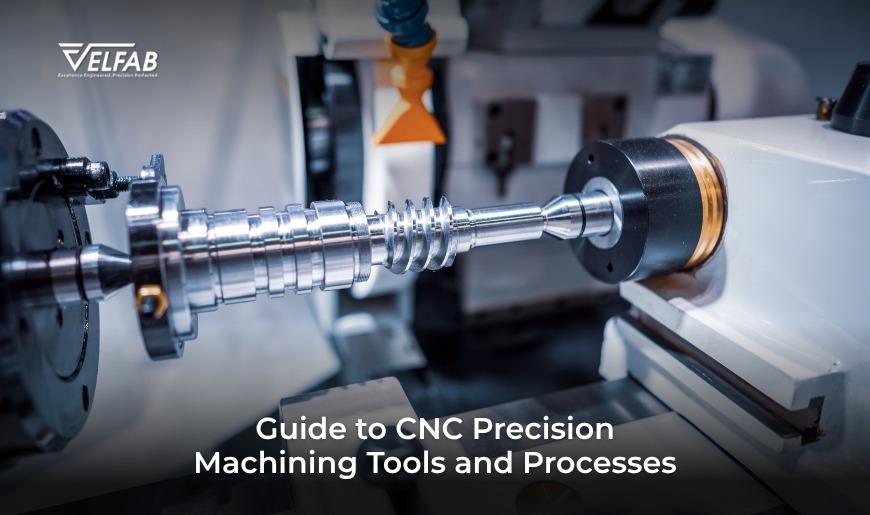

This is where precision machining for oil and gas plays a decisive role. By ensuring reliable, high-performance components built to withstand extreme conditions, precision machining reduces failures, prevents unexpected shutdowns, and keeps operations running smoothly.

The High Cost of Downtime in Oil & Gas

Downtime in oilfield operations isn’t just about idle machines—it’s about delayed projects, workforce inefficiencies, and penalties for missed delivery schedules. Offshore rigs, for instance, can lose hundreds of thousands of dollars per day if equipment isn’t operational. That’s why maintaining component reliability is not optional; it’s critical.

What Causes Downtime in Critical Equipment?

Oil and gas operations demand more from machinery than most industries. Downtime often occurs due to:

- Wear and tear of components like valves, seals, flanges, and shafts that are constantly exposed to high pressure and heavy usage.

- Delays in sourcing replacement parts, especially when custom designs or international shipments are involved.

- Incompatibility or poor fit of off-the-shelf components, which often fail to meet the tight tolerances required.

Extreme operating conditions—including high pressure, corrosive chemicals, and fluctuating temperatures—that accelerate failure.

The Role of Precision Machining in Reducing Failures

At Velfab, we understand that downtime is the enemy of productivity. That’s why we specialize in delivering custom machined parts for oilfield equipment that directly address these challenges:

Custom-Fit Components with Tight Tolerances

- CNC machining ensures parts are built with extreme accuracy, offering perfect fit and reliable performance. This eliminates the risk of leaks, misalignments, or early wear.

Machining for Harsh Environments

- Using high-performance materials and advanced machining techniques, components are designed to withstand pressure, corrosion, and temperature variations without compromising durability.

Reverse Engineering and Retrofit Solutions

- When older parts are unavailable or discontinued, precision machining enables reverse engineering to recreate or upgrade components—reducing lead times and extending equipment life.

Common Oil & Gas Parts That Require Precision Machining

Precision machining is at the heart of reliable oilfield operations. Some of the most critical parts include:

- Valve bodies and stems

- Pump components (impellers, casings, shafts)

- Compressor parts

- Skid-mounted modular parts

- Flanges, hubs, and connection blocks

These components often operate under extreme stress, making CNC machining for offshore rigs and refineries indispensable.

Conclusion: Invest in Precision. Avoid the Cost of Failure.

In oil and gas, the choice is clear—invest in precision today or pay for downtime tomorrow. High-performance machined components may seem like a small part of the bigger operation, but they make the difference between seamless production and costly breakdowns.

At Velfab, we deliver precision machining for oil and gas operations that helps companies minimize downtime, maximize reliability, and stay competitive in a demanding industry.