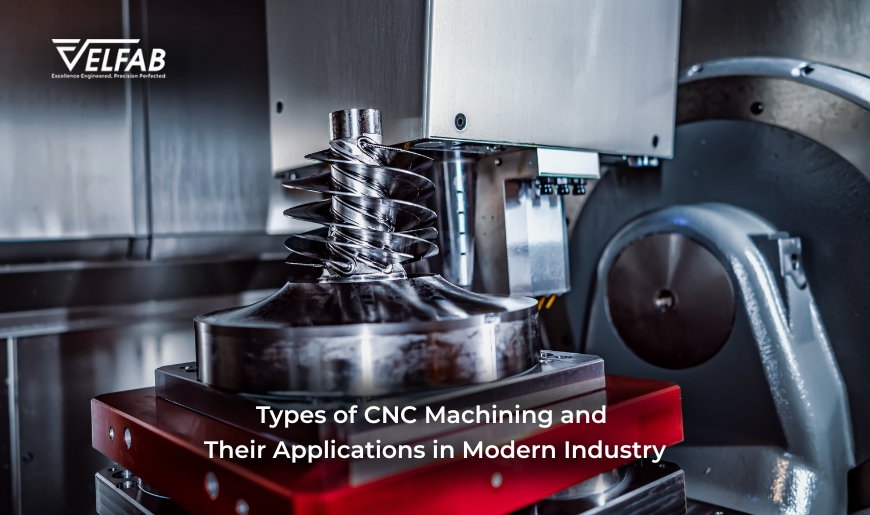

Types of CNC Machining and Their Applications in Modern Industry

Walk into any modern manufacturing unit today, and you’ll most likely find CNC machines quietly shaping the future—quite literally. From automotive components to delicate medical implants, CNC machining is at the heart of how industries bring precision, speed, and consistency to production.

But what exactly are the different types of CNC machines? And how do they fit into real-world industrial needs? Let’s break it down in simple terms.

1. CNC Milling Machines: The All-Rounders

If there’s one machine that truly does it all, it’s the CNC milling machine. Think of it as a super-precise sculptor that can cut, drill, and shape materials from different angles. Using rotating tools, it carves out detailed parts from metal, plastic, or other solid materials.

Where it shines: Ideal for aerospace, automotive, and even prototype development—anywhere intricate cuts and angles are involved.

2. CNC Lathes: Masters of Symmetry

Imagine a pottery wheel—but for metal and with laser-sharp precision. CNC lathes rotate the workpiece while a tool shapes it, making them perfect for creating round objects like rods, rings, and cylinders.

Where it’s used: Manufacturing of shafts, screws, fittings, and other cylindrical parts across automotive and mechanical industries.

3. CNC Routers: Fast and Versatile

CNC routers are like the energetic younger sibling of milling machines. They’re lighter, faster, and commonly used for softer materials like wood, foam, plastic, and even some metals.

Where they belong: You’ll find them in furniture workshops, signage companies, and any industry that needs large, detailed surface work.

4. CNC Plasma Cutters: Power Meets Precision

Using a high-velocity jet of hot plasma, these machines slice through electrically conductive materials like steel and aluminum with impressive ease. They’re fast, powerful, and perfect for cutting thick sheets where manual precision would fall short.

Commonly found in: Metal fabrication shops, automotive repair units, and construction equipment manufacturers.

5. CNC EDM (Electrical Discharge Machining): For the Tough Jobs

Some materials are just too tough (or too delicate) for traditional cutting methods. That’s where EDM steps in. It uses electrical sparks to erode material—slowly, but very precisely. Wire EDM, a popular version, is great for creating tiny, intricate parts.

Used for: Mold making, die creation, and aerospace parts that need microscopic accuracy.

6. CNC Laser Cutters: Clean Cuts, No Contact

Lasers might sound like something out of a sci-fi movie, but in the industrial world, they’re real workhorses. CNC laser cutters deliver ultra-clean, detailed cuts without ever physically touching the material.

Applications include: Electronics, signage, decorative panels, and fine-cut metal or acrylic designs.

Why All This Matters

The beauty of CNC machining is that there’s no one-size-fits-all. Each machine type brings something unique to the table. Whether you’re working on large batches of automotive parts or one-off custom designs, choosing the right CNC process can save time, reduce waste, and improve quality.

At Velfab, we believe in making technology work smarter for you. CNC isn’t just about machines—it’s about mastering precision, speed, and innovation in a way that fits your specific industry needs.

Final Thoughts

So, the next time you hold a perfectly shaped gear or a sleek piece of metal furniture, remember—there’s a high chance it came from the hands of a CNC machine. From big factories to small workshops, CNC machining continues to shape the future of manufacturing—one precise cut at a time.